In the realm of cutting technologies, precision is key. A Manual Cutting Machine offers a hands-on approach for craftsmen and manufacturers alike. With a variety of options available, selecting the right one is crucial for achieving impeccable results.

The manual cutting machines on our list vary in features and capabilities. Some excel in intricate cuts, while others handle bulk materials with ease. Each machine caters to specific cutting needs, allowing users to find the perfect match for their projects. However, choosing the best manual cutting machine can sometimes feel overwhelming, especially with so many options available.

As you explore the top manual cutting machines, consider the flaws and limitations that come with each model. An ideal machine for one project might not suit another's requirements. Understanding these nuances is essential for anyone serious about precision cutting. By reflecting on your specific needs, you're better positioned to make an informed choice.

Manual cutting machines are essential tools in many industries. They provide precision and control that automated machines cannot always offer. These machines come in various shapes and sizes to meet different cutting needs. Many users appreciate their straightforward design and ease of use. However, operating them requires skill and attention.

When selecting a manual cutting machine, consider the material you'll work with. Some machines excel with specific materials while struggling with others. A user might find that the blade dulls quickly, necessitating frequent replacements. These machines demand regular maintenance to ensure optimal performance. Choosing the right blade is equally important. Not all blades work well with every task, and a mismatched blade often leads to less than perfect cuts.

It's crucial to prioritize safety while using these machines. Injuries can occur if proper techniques aren't followed. Many users may underestimate the risks involved. It's essential to wear protective gear and be mindful of hand placement. Overall, while manual cutting machines offer various benefits, the user must remain proactive and reflective about their practices to minimize errors and enhance efficiency.

This bar chart displays the cutting accuracy of the top 10 manual cutting machines. The accuracy is measured in millimeters, showcasing the precision each machine offers.

When selecting a manual cutting machine, specific features are crucial for precision. Blade materials and types significantly influence cutting accuracy. Quality blades made from high-carbon steel or tungsten carbide provide longer life and sharper cuts. A recent industry report indicates that machines with solid blades reduce cutting errors by up to 30%.

Another vital aspect is the cutting mechanism. Many machines use either guillotine or rotary mechanisms. Guillotine options often offer straight cuts, while rotary cutters allow for more complex shapes. According to a survey, around 60% of users prefer rotary cutters for their versatility and precision in intricate designs. The ease of adjusting blade depth is also a key feature, allowing users to customize their cuts based on materials.

Moreover, consider the ergonomic design of the machine. User comfort impacts productivity and results. Machines with padded handles or adjustable heights can lessen fatigue. Industry data shows ergonomic designs can enhance user efficiency by 20%. However, not all machines offer these features, leaving potential room for errors and dissatisfaction. An informed choice balances these features and personal needs.

When selecting a manual cutting machine, precision is key. A good machine offers clean edges and effortless cuts. These tools cater to various materials, from paper to fabric, and even lightweight metals. Your choice should depend on the specific use and desired accuracy.

Consider the weight and stability of the machine. Heavier models provide better control, but they may be less portable. Check the blade type as well. Certain blades perform better on specific materials. Finding the right combination can save time and enhance results.

Remember, practice makes perfect. It’s essential to familiarize yourself with the machine’s mechanics. Waiting for the right moment to cut can make a difference. A steady hand and attention to detail are paramount. Cleaning and maintaining the machine regularly will ensure longevity. Prioritize proper storage to protect the blades from damage.

| Ranking | Model | Cutting Width | Material Compatibility | Weight | Price |

|---|---|---|---|---|---|

| 1 | Precision Cutter A | 36 inches | Paper, Vinyl | 15 lbs | $120 |

| 2 | Manual Cutter B | 24 inches | Cardstock, Fabric | 12 lbs | $85 |

| 3 | Cutting Machine C | 30 inches | Leather, Paper | 20 lbs | $150 |

| 4 | Classic Cutter D | 42 inches | Cardboard, Plastic | 18 lbs | $200 |

| 5 | Versatile Cutter E | 32 inches | Fabric, Paper | 14 lbs | $110 |

| 6 | Heavy-Duty Cutter F | 40 inches | Wood, Cardboard | 25 lbs | $250 |

| 7 | Precision Craft Cutter G | 28 inches | Paper, Plastic | 13 lbs | $95 |

| 8 | Compact Cutter H | 20 inches | Vinyl, Leather | 10 lbs | $75 |

| 9 | Ultimate Cutter I | 35 inches | Fabric, Cardstock | 22 lbs | $180 |

| 10 | Economy Cutter J | 18 inches | Paper, Vinyl | 8 lbs | $50 |

When it comes to precision cutting, every detail matters. Manual cutting machines offer various features that affect performance and accuracy. Not all machines deliver the same level of precision. Some may struggle with intricate designs, leading to uneven edges. Users often find that blade quality plays a vital role. Dull blades can cause jagged cuts, necessitating multiple passes. A steady hand is required, as any slight movement can affect the outcome.

Comparing different machines highlights strengths and weaknesses. Some models excel in cutting thick materials but lack finesse for delicate jobs. Others might be lightweight and easy to handle but may compromise on stability. Weight distribution plays a crucial role in precision. An unbalanced machine can tilt or wobble, leading to flaws. Small adjustments to cutting angles can also significantly impact results. Users frequently encounter challenges when adapting to varying material types.

Precision is an evolving art. Even with top machines, consistency can be a struggle. It often requires frequent practice and careful adjustments. Learning curves differ widely among users. What works for one might not be effective for another. Seeking out feedback from peers can be beneficial yet also overwhelming. The journey to mastering precision cutting is filled with trial and error.

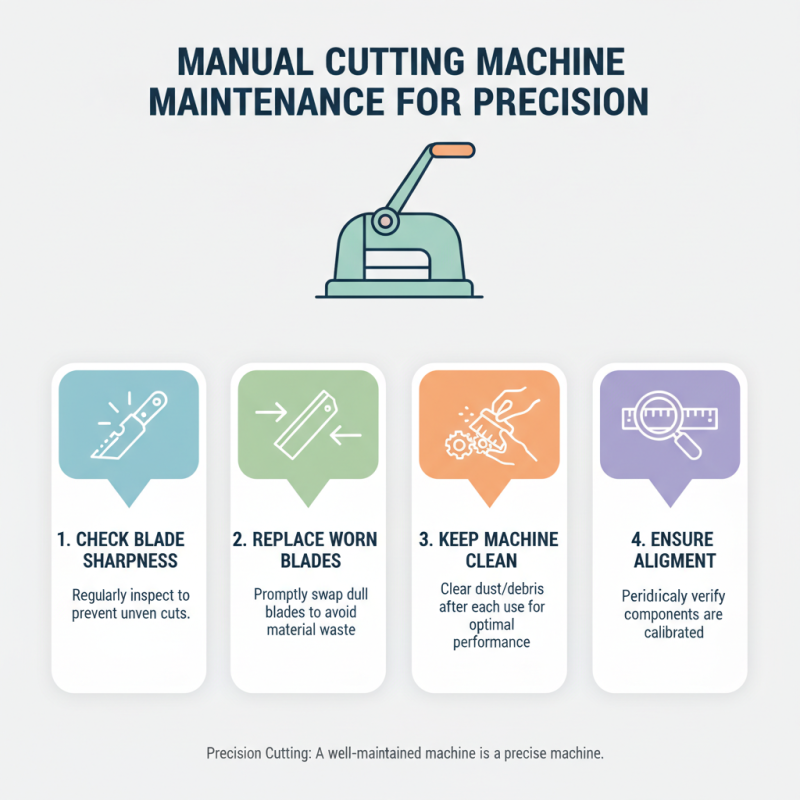

Maintaining manual cutting machines is essential for achieving precision. Regular checks on blade sharpness can prevent mistakes. A dull blade can lead to uneven cuts and wasted materials. It’s crucial to replace worn-out blades promptly. Ensure the machine is clean after each use. Dust and debris can affect performance over time.

Proper usage techniques should not be overlooked. Hold the material firmly during the cutting process. This helps prevent slipping and results in cleaner edges. Some users might neglect this step. It can cause frustration when the cuts aren't straight. Always follow the manufacturer’s guidelines to maximize efficiency. If the machine feels off, take a moment to assess the issue. Ignoring subtle signs can lead to significant problems later.