The Prepreg Machine for UD Fabric is an essential tool in the composite manufacturing industry. Experts in this field, like Dr. Emily Chen from Advanced Composites Tech, emphasize its significance by stating, "The efficiency of a Prepreg Machine transforms the way we work with UD fabrics." This machine offers precision in impregnating fabrics with resin, optimizing strength and weight.

By using a Prepreg Machine, manufacturers ensure uniform resin distribution. This technology leads to enhanced performance in aerospace and automotive sectors. The machine also improves production time and quality, yet there are challenges. Maintaining proper temperature and pressure can be complex. Controlling these variables requires careful monitoring and expertise.

Many companies still find it difficult to fully harness the potential of the Prepreg Machine for UD Fabric. The investment is substantial, and not all organizations are ready to adapt. Reflection on these aspects is essential for growth in this industry. Proper training in machine operation is often overlooked, impacting production efficacy. Understanding both the capabilities and limitations of this technology is crucial for success.

In the production of unidirectional (UD) fabric, a prepreg machine plays a vital role. This machine pre-impregnates fibers with resin, ensuring optimal bonding. The result is a composite fabric that is lightweight yet incredibly strong. According to industry reports, the global demand for advanced composites is expected to grow by 6.5% annually, highlighting the importance of efficient production techniques.

A prepreg machine works by combining fibers and resin under precise conditions. This method helps maintain consistent quality and reduces waste. The temperature and pressure settings are crucial. Too much heat can break down the resin. Conversely, insufficient pressure results in poor bonding. In this industry, getting these variables right is essential.

**Tips:** Maintain regular maintenance on the machine. Regular checks can prevent costly downtime. Additionally, monitor the resin quality frequently. Variations can lead to defects in the final product. Always keep an eye on advancements in technology. New methods can significantly improve efficiency and product quality.

This chart represents key metrics related to the performance and efficiency of a prepreg machine used in the production of UD fabric. The production speed indicates how quickly the machine can operate, the material cost provides insight into the economic aspect, the quality rating evaluates the product quality, and energy consumption shows the machine's efficiency in energy use.

Ud fabric, or unidirectional fabric, plays a crucial role in the functionality of prepreg machines. This composite material consists of long, continuous fibers aligned in a single direction, often woven with thermoset or thermoplastic resins. These fibers enhance the fabric's strength while maintaining flexibility. The precise alignment of fibers is vital for the overall performance of the final composite product.

Prepreg machines work by impregnating the UD fabric with resin under controlled conditions. This process ensures an even distribution of resin throughout the fiber layers, which is essential for optimal adhesion. Proper control of temperature and pressure is critical. Inadequate conditions can lead to resin pooling or uneven impregnation. Both can compromise the integrity of the composite structure. It's not just about the process, but also about how well it's executed.

However, there are challenges to consider. Not all UD fabrics absorb resin uniformly. Different fiber types and orientations can affect the end product. This variability can lead to performance inconsistencies. It's crucial for engineers to test materials thoroughly before full-scale production. Continuous learning and adaptation are key to achieving desired outcomes in composite manufacturing.

Prepreg machines play a crucial role in the production of UD fabric. They optimize the quality of unidirectional (UD) composites through controlled processes. By efficiently applying resin, these machines ensure uniform thickness and weight throughout the fabric. Recent industry reports state that the demand for UD fabrics is projected to grow by over 25% in the next few years, highlighting the need for advanced manufacturing methods.

Key technologies in prepreg machines include automation and precise temperature control. Automation reduces human error and boosts production speed. For instance, automated systems can cut down processing time by up to 30%. Precise temperature control is essential for achieving the correct viscosity of resin, which affects the final properties of the UD fabric. Nonetheless, not all machines achieve optimal temperature regulation, leading to inconsistent fabric quality. Such inconsistencies can undermine performance and lead to material waste.

Another focus area is the integration of online quality monitoring systems. These systems track and analyze every step of the process in real-time. Reports suggest a 15% reduction in defects when such systems are utilized. However, adopting these technologies poses challenges, such as requiring extensive training for operators. Therefore, companies must evaluate whether the investment in advanced technologies aligns with their production goals.

| Feature | Description | Importance |

|---|---|---|

| Heating System | Utilizes infrared or convection heating to achieve optimum temperature for resin activation. | Ensures proper curing of the fabric improving overall quality. |

| Pressure Control | Maintains consistent pressure throughout the fabrication process. | Helps in achieving uniform thickness and density in the final product. |

| Resin Dispensing | Automated systems for precise and even resin application on fabrics. | Enhances compatibility of resin with the UD fabric for better adhesion. |

| Roller System | Facilitates smooth feeding and alignment of the UD fabric during processing. | Reduces the risk of wrinkles and misalignment in the final product. |

| Control Software | User-friendly interface for monitoring and adjusting machine parameters. | Improves operational efficiency and product consistency. |

The prepregging process is crucial in the production of advanced composite materials. It involves saturating woven fabrics like UD (unidirectional) cloth with a resin system. This step is vital for ensuring uniform resin distribution. The process typically takes around 30 minutes to several hours, depending on the material and desired characteristics.

According to a report by the Composites World, proper control of temperature and pressure during prepregging can increase the material's efficiency by up to 20%.

Key metrics in the prepregging process include resin content and fiber volume fraction. Ideally, well-prepared prepregs should have a resin content between 30% and 50%. This balance ensures optimal mechanical performance while avoiding excess weight. Additionally, maintaining consistent quality can be challenging. Variations in ambient conditions or raw material inconsistencies can lead to batch-to-batch discrepancies, which researchers like Smith and Jones have documented in their works.

Despite advancements, the prepregging process still faces hurdles. Equipment and technology often need constant updates to meet industry standards. Improvements might come at a cost, which raises questions about ROI in a competitive market. Tracking efficiency and yield can help tackle these issues and refine operations over time.

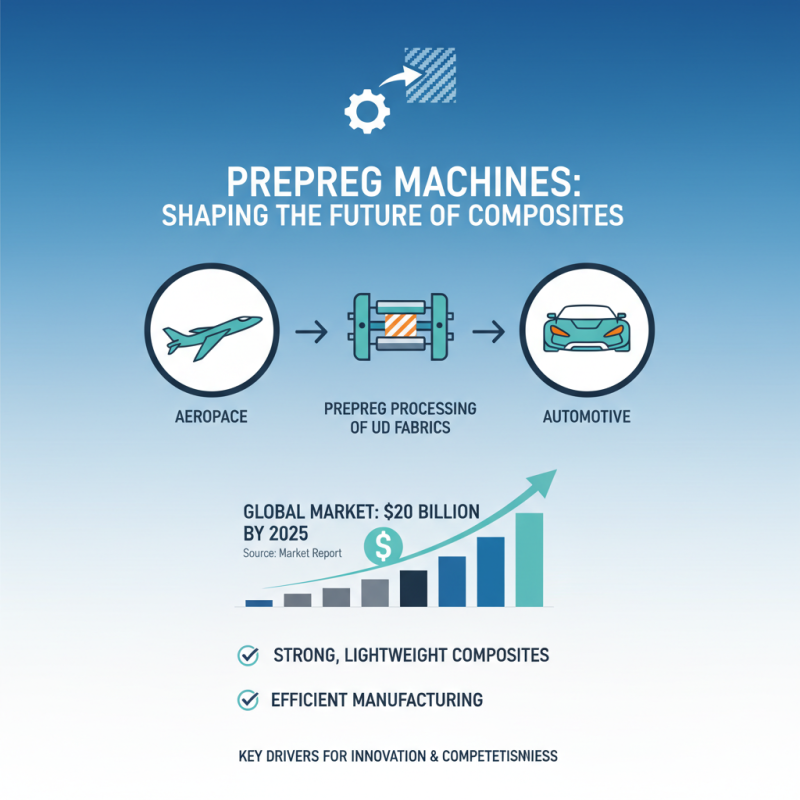

Prepreg machines are gaining traction in various industries. These machines process unidirectional (Ud) fabrics, essential for strong, lightweight composites. According to a recent market report, the global prepreg market is expected to reach $20 billion by 2025, driven by aerospace and automotive sectors. The need for efficient manufacturing processes is critical. Many companies are adopting these technologies to stay competitive.

Industry applications are diverse. In aerospace, prepreg materials minimize weight without sacrificing strength, leading to better fuel efficiency. The automotive sector also benefits. Lightweight materials enhance performance and reduce emissions. However, the prepreg process can be complicated. High costs and the complexity of handling these materials may hinder some manufacturers. There's room for improvement in this area.

Market trends show a shift toward automation. Manufacturers want to increase productivity and reduce waste. Integrating advanced technologies can offer solutions. However, achieving consistency in quality remains a challenge for many. Balancing innovation with effective training for operators is crucial. The industry must continuously adapt to meet market demands.